Electrolytic Vs Ceramic Decoupling Capacitor

In addition multi layer ceramic capacitors mlccs are available in a wide range of packages and capacitance values.

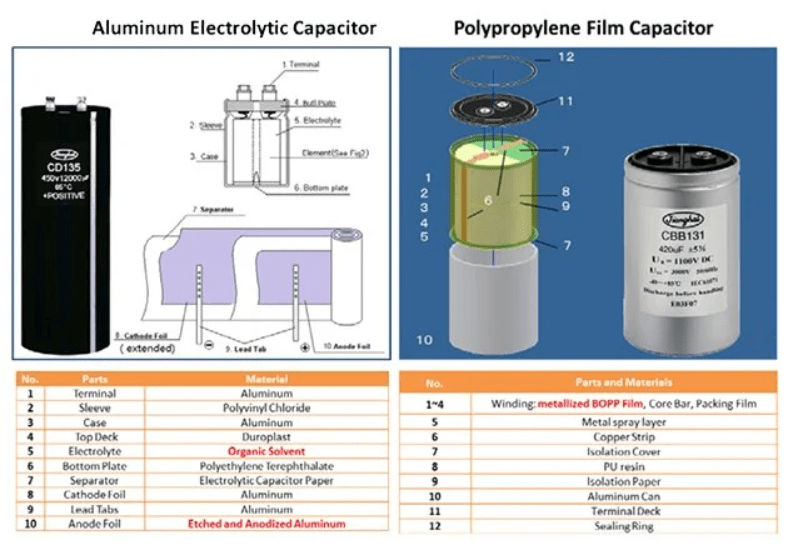

Electrolytic vs ceramic decoupling capacitor. Can a single large multilayer ceramic capacitor replace the classic electrolytic ceramic decoupling capacitor arrangement. For this reason decoupling capacitors are added to the circuit in order to smooth out the power supply voltage. Ceramic capacitors are an excellent option for decoupling applications in hf circuits. An electrolytic capacitor is a type of capacitor that uses an electrolyte in order to increase its capacitance.

Ceramic capacitors and electrolytic capacitors are two main types of capacitors that are widely used in electrical and electronic components. What is an electrolytic capacitor. Due to their very thin dielectric oxide layer. In fact many ceramic capacitors i suspect are the exact same part but with different part numbers the same 4 7µf capacitor being sold as both a 35v and 50v capacitor under different labels.

Bias voltage is identical save for the lower voltage one having its graph truncated at its rated voltage. In addition multi layer ceramic capacitors mlccs are available in a wide range of packages and capacitance values. Mainly we are using ceramic and electrolytic capacitors in our circuits but most of us don t know about the difference between them. Unlike bypass capacitors there are not much riles to choose the value of a decoupling capacitor.

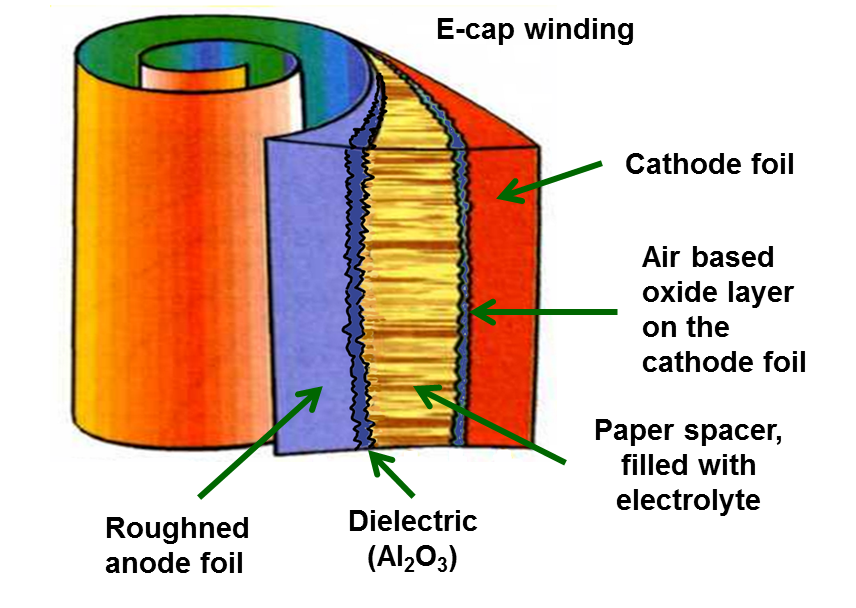

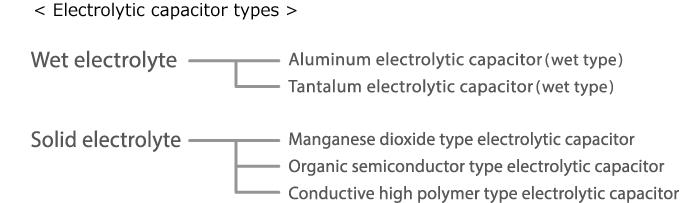

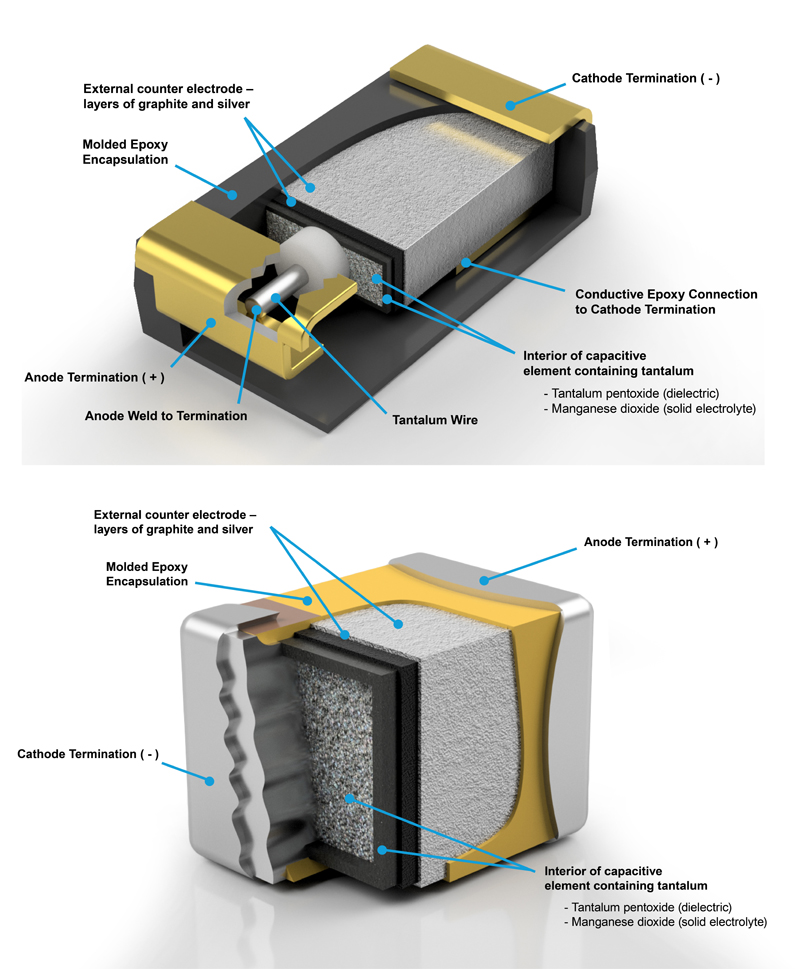

So most of the time we d. Why do some devices use electrolytic capacitors instead of ceramics for small value components. Value of the decoupling capacitor. A solid liquid or gel electrolyte covers the surface of this oxide layer serving as the cathode or negative plate of the capacitor.

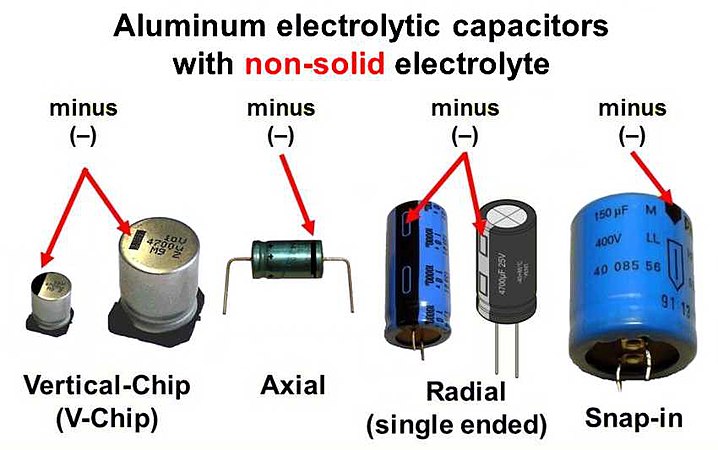

The most used type of capacitors for low frequency smoothing is the electrolytic capacitors and the capacitors used for high frequency smoothing are the surface mount ceramic capacitors. Class 1 capacitors are more accurate and stable over a larger range of temperatures while class 2 capacitors offer more volumetric efficiency more capacitance per unit volume. The graph of some mlccs capacitance vs. Class 1 and class 2.

The ceramic capacitor uses a thin ceramic layer as the dielectric medium whereas the electrolytic capacitor uses an ionic liquid as one of the sheets of the capacitor. Switching type aluminium electrolytic capacitors are commonly used for decoupling applications in low frequency and medium frequency. Ceramic capacitors are an excellent option for decoupling applications in hf circuits. A good rule of thumb for digital circuits is to use a single 100nf ceramic capacitor for each logic integrated circuit as well as a single larger up to a few hundred µf electrolytic capacitor per board or circuit segment.

Which type of capacitor to use for matching the data sheet. There are two main types of ceramic capacitors.