Electrical Thermal Imaging Standards Australia

Currently there is no standard for thermographic scanning in australia.

Electrical thermal imaging standards australia. Used in an environment in which the normal use. Sus standards for t the values in this table will provide reason able guidelines. We will provide you with fast and accurate evaluations of thermal imaging results. In 2012 a code of practice was created to help create uniformity amongst thermal imaging technicians across the nation.

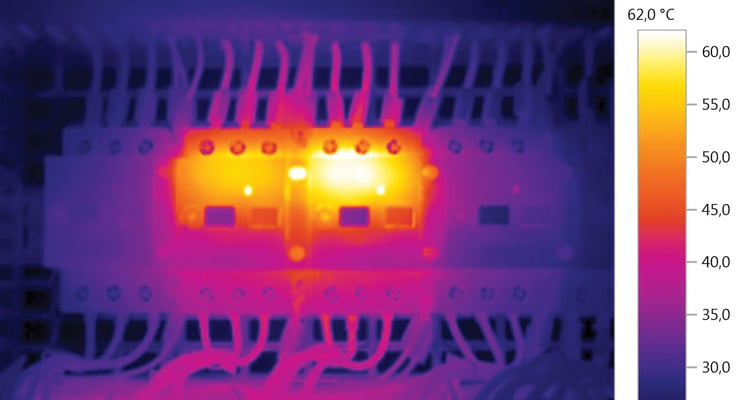

To thoroughly inspect and thermograph electrical mechanical services switchboards. Many electrical and mechanical services contractors are carrying out thermographic inspections without any certification at all neither category i nor category ii and are therefore carrying out work that has no validity under the australian standards. It is based on the central office draft of iec technical report 943 1989 guide for the specification of permissible temperature and temperature rise for parts of electrical equipment in particular for terminals but is presented. An alternate method of evalu ation is the standards based temperature rating system as discussed in section 8 9 2 conducting an ir thermographic inspection electrical power sys tems maintenance and testing by paul gill pe 1998.

This standard was prepared jointly by the standards australia committees on industrial switchgear and controlgear and power switchgear as a guide for engineers responsible for the determination of temperatures of components forming parts of electrical equipment. Thermal imaging cannot see through solid objects. Currently standards exist for the certification of personnel operation of equipment and inspections of electrical mechanical and structural systems. Infrared thermal imaging as per as nzs 3019 clause 5 8 the integrity of switchboard connections should be tested out with a thermal imaging device.

Supplied with electricity through an electrical socket outlet and. When the australian standard for thermal imaging is introduced we will incorporated these into our comprehensive processes. Electrical board cover plates are opened on all boards to expose the electrical wiring and components. Many electrical and mechanical services contractors are carrying out thermographic inspections to a level which their certification simply does not permit.

We understand electrical components and their limitations. Under chapter 4 part 4 7 of the work health and safety regulation 2011 whs reg a person conducting a business or undertaking pcbu at a workplace must ensure that the electrical equipment is regularly inspected and tested by a competent person if the electrical equipment is. Thermal imaging testing procedure. Thermographic solutions comply with these standards.

Australian standards as nzs3000 2007 as nzs3017 2007 and as nzs3019 2007. The person performing the. Our thermographers are accredited to australian standards. Our infrared technicians are the best and most experienced in western australia with thousands of hours of experience in the field each and are certified to rigorous australian and international iso standards as iso18436 7 with aindt pcn bindt and asnt certifications they are qualified to work anywhere in the world.

Switchboard covers need to be removed for accurate results.