Electrical Heat Tracing Calculation Xls

The first method is known as electrical heat tracing and the second is known as steam tracing.

Electrical heat tracing calculation xls. The provider of electrical heat tracing solutions to protect people processes and infrastructure. This includes products such as transformers control and monitoring panels power connections heating cable end terminations and related accessories. Electrical heat tracing may be described as an insulated electrical heating cable which is spiralled around the process fluid pipe after which the pipe. Electrical heat tracing may be described as an insulated electrical heating cable which is spiralled around the process fluid pipe after which the pipe and tracing is insulated with the appropriate type and thickness of insulation lagging material.

The heat loss from a pipe is contingent on the pipe size external insulation type thickness of the insulation and overall temperature gradient. Supermec provides a complete system from design to installation commissioning and testing. Heat tracing on a pipe is most efficient when the pipe is properly insulated. For 19 and beyond.

Heat trace cable calculator. Heat trace the demands placed on heat tracing systems vary based on the design parameters specific to each application. Industrial electric heat supply made fast simple and accurate. Current heat trace technology utilizes a self regulating polymer that controls the wattage of the element.

To meet these needs thermon manufactures the widest variety of electric heating cables and control systems in the world. The term heat tracing is inclusive for two methods used in the conservation of temperature. The experts in electrical heat tracing systems providing turnkey project services around the world. In some cases the heat tracing system can be used for system heat up at initial startup or after a power shutdown.

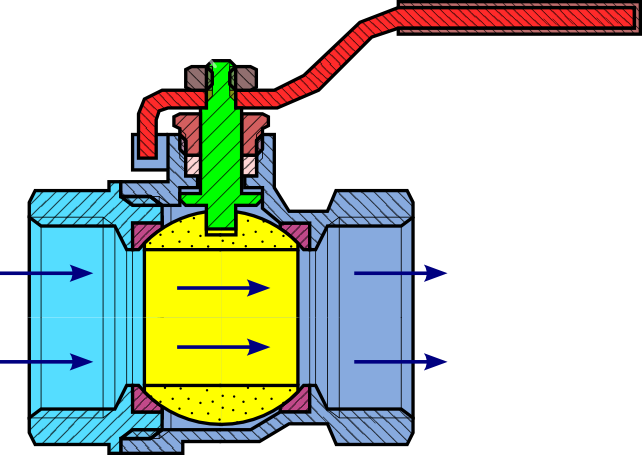

3rtd sensor or control thermostat. The electric heating is achieved by utilizing a resistant element that is run alongside the piping or vessel. Electric heat tracing cable2 self regulating power limiting parallel constant watt or series constant watt. The first method is known as electrical heat tracing and the second is known as steam tracing.

While a temperature controller is recommended for all heat tracing applications in this case it should be considered essential. Heat trace is an electrical system used to maintain or raise the temperature of pipes and vessels. Liquid flowing through a pipe greatly increases heat loss and this calculator does not yet support calculations for flowing liquids. Tion of a bill of materials for an electric heat tracing system.

In line t splice kit permits two or three cables to be. An electrical heat tracing system is much more than just the heating cable.